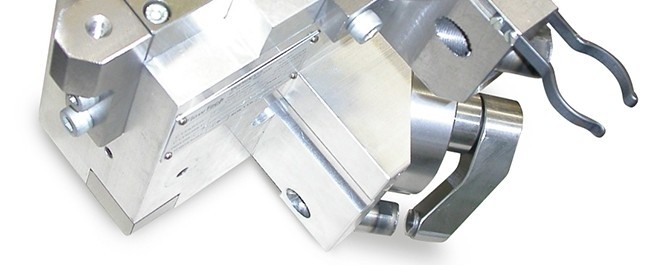

Assembly

Assembly of groups and subgroups takes place according to the documentation, manuals or instructions of the customer or according to our own procedure or manual we develop on the basis of the technical documentation handed over. We are also capable of developing the technical documentation on the basis of the customer’s design or sketch. If assembly jigs or auxiliaries are required, we develop our own manufacturing documentation and ensure manufacturing at partner firms in CZ and SK. The documentation also include manuals and procedures for checking and packing.

Provision of parts for assembly

We ensure the parts required for assembly at the existing supplier all over the world or at the partner firms in CZ and SK. For manufacturing, we ensure purchase of raw material with the certificate. When the parts are being manufactured, we closely cooperate with the manufacturer on a design of the manufacturing documentation, manufacturing auxiliaries and in particular checking procedures so that 100% manufacturing quality is guaranteed.

Quality check, storage and logistics

Assembly includes a checking workplace with the Zeiss coordinate measuring machine on which the parts are checked before their own assembly and subsequently stored. We own storage areas for storage of a sufficient amount of parts in order to be capable of delivering within short delivery terms and quickly responding to the customer’s requirements. On the customer’s request, we pack the goods and subsequently ensure transport to the customer including clearance.

Advantages of cooperation:

- Decrease in portfolio of suppliers

- Provision and storage of all the necessary materials

- Assistance in development of new products

- Flexible prototyping

Contact our specialist for more information.