Magnetic couplings

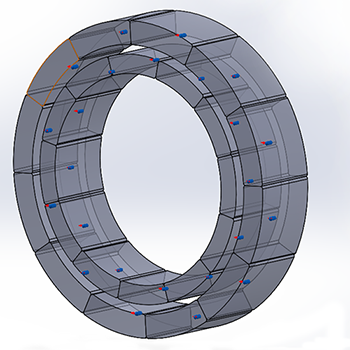

The magnetic couplings enable torque transmission without the need of a physical contact of their individual parts. They work on the same principle as electric motors with permanent magnets. The coupling consists of two “cylinders” with bonded magnets forming a multipole structure - an internal cylinder with magnets bonded to the external diameter, a larger cylinder with magnets bonded to the internal diameter, both cylinders are inserted in each other. An external part is usually connected to a drive unit. The poles on one cylinder are positioned against opposite-magnetized poles of another cylinder (North-South) and generate the strong magnetic field, thanks to which both cylinders rotates synchronously. When overloaded, the poles “slide over” each other and try to take a new position with opposite poles against each other. The torque is generated by the magnetic field in a slot between both cylinders, the torque increases or decreases with a change of the slot height.

Use of magnetic couplings:

The magnetic couplings can be found in pumps, compressors, dispensers and other applications. Where the extremely toxic substances or other aggressive media are used, individual parts of the equipment should be hermetically sealed. The magnetic couplings act as a “barrier” and their capability of “sliding over” during overloading minimizes a risk of damage to the pump and connected equipment.

Further advantage of the magnetic couplings is the fact that they do not require maintenance, they help reduce vibrations, partially compensate misalignment of shafts of individual parts (cylindrical) and limit the maximum torque of parts.

Design of magnetic couplings:

In addition to the “cylindrical” design, the synchronous magnetic couplings are also manufactured as “disc” couplings that can be used where a sufficient space is not available for the cylindrical coupling. It consists of two flat parts with magnets bonded to internal sides positioned against each other. The disc-type magnetic couplings offer all the advantages as the “cylindrical” magnetic couplings but transmit a lower torque due to a high axial load of connected shafts.

Magnet types in couplings:

Neodymium as well as samarium permanent magnets are used in the magnetic couplings. An application determines which of them is to be used. The neodymium-based permanent magnets have a higher magnetic flux, thus they transmit a higher torque but their use is limited by a thermal class of the magnet. These magnets can be used for temperatures approx. up to 230°C and moreover they are sensitive to corrosion. The samarium magnets succeed the neodymium magnets where they are unsatisfactory. The samarium-based magnets have a high temperature resistance up to 350°C and an excellent corrosion resistance.

Manufacturing of magnetic couplings in PZK BRNO:

We manufacture synchronous magnetic couplings with permanent magnets. We focus on special applications having a high demand for the design quality. In our own testing laboratory, we test magnetic properties of individual magnets as well as resultant assemblies and strength of bonded joints. We check dimensions on our own coordinate measuring machine (CMM) and perform balancing on our own balancing machine. Using the finite element method (FEM), we are able to design or optimize a suitable solution.

We specialize in:

- Calculation of torque of magnetic couplings

- Constructional design of magnetic couplings

- Prototyping

- Serial production of magnetic couplings

We will be happy to cooperate on development and manufacturing of magnetic couplings for your applications, please contact our specialist.